How Kopp-Voracek Uses 3D Models/Data for High-Quality Composite Production

kopp-voracek spol. s r.o. is a manufacturer of composite products, specializing in carbon fiber parts. We take pride in using the latest technology to create high-quality products for our customers. One of the key technologies we use is 3D data processing, which allows us to develop a manufacturable design and prepare patterns for molding.

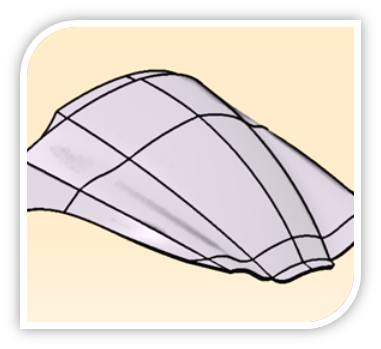

At kopp-voracek, we start by using advanced CAD software to process 3D data and develop a digital model of the product. This involves manipulating the data to create a 3D model that accurately represents the product, and allows us to make necessary changes before the production process begins. Once the digital model is complete, it serves as a starting point for the preparation of patterns or real models that will be used for the molding process.

Our composite production process involves the use of two techniques - vacuum infusion and autoclave curing. Infusion is a process where a dry preform is placed in a mold and resin is then drawn into the mold using vacuum pressure. This allows us to achieve a uniform distribution of resin, resulting in a strong and lightweight composite part. Autoclave curing, on the other hand, involves placing the part in an autoclave and applying heat and pressure to cure the resin. This ensures that the composite has the desired properties and meets customer requirements.

But that's not all - at kopp-voracek, we also use 3D models/data for cutting carbon fiber parts from sheets. We produce our own carbon fiber sheets and use 3D models/data to guide the cutting process on our CNC machines. This allows us to precisely cut the carbon fiber sheets into the required shapes and sizes for the final product. By using 3D models/data, we can ensure that each part is cut to exact specifications, resulting in high-quality products that meet customer requirements.

Using 3D models/data in composite production has many advantages. It allows us to reduce waste and save time, as we can optimize the production process and ensure that each part is manufactured accurately. Additionally, it allows us to produce complex parts that may be difficult or impossible to produce using traditional methods. This gives us a competitive edge in the market, as we can produce high-quality composite products that meet customer requirements in a cost-effective and efficient manner.

In conclusion, kopp-voracek spol. s r.o. uses 3D models/data to develop manufacturable designs, prepare patterns for molding, and manufacture composite products using infusion and autoclave curing techniques. By leveraging the latest technology and our expertise in composite production, we are able to produce high-quality products that meet customer requirements and exceed expectations.